Researchers at Chalmers University of Technology have announced a new breakthrough in battery tech that might be a big help to electric motorcycle designers.

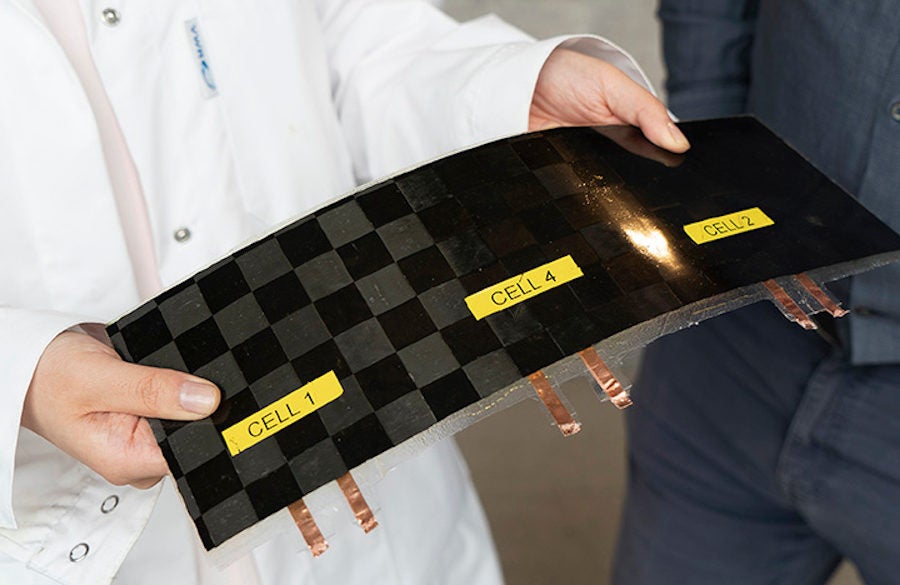

Scientist at the Swedish university say they’ve put together a structural battery that has 10 times the performance of previous versions. It’s made of carbon fibre, which serves as the battery’s electrode, conductor, and load-bearing material. This clever engineering means the battery can serve as a stressed member of the chassis—or as the chassis itself.

This has the potential to revolutionize electric motorcycle design, in the long-term. One of the biggest problems with current electric motorcycles is battery weight. While designers are cutting weight on electric motorcycles with trick chassis and motor design, the big problem is—the big battery. Electric bikes need big batteries if they want decent range, and in turn, that means extra weight.

If designers can somehow figure out how to build an electric motorcycle with the battery as the chassis, that would allow designers to cut weight elsewhere. This is basically what Harley-Davidson did with the Pan America 1250, and what Ducati did with the Panigale V4—except those companies used the engine as the main chassis member, bolting smaller sub-frames onto it. With a structural battery, not only could the designers bolt sub-frames to the battery, those sub-frames themselves could also function as batteries. Win-win.

Unfortunately, this technology breakthrough might not help with a different problem in the electric motorcycle scene—expense. Currently, despite the many advantages touted by battery bike fans (insta-torque, low maintenance costs), the reality is that electric motorcycles are still priced much higher than most gasoline-powered bikes. Structural batteries won’t solve that problem, and they may drive the price up further.

另一个问题:现在,锂离子电池仍然具有比基于碳纤维的结构电池更好的能量密度。自2000年代初开始发展以来,碳纤维电池已经走了很长的路径,但在替代现有电动摩托车电池之前,他们仍然有很长的路要走。

How does it work?

According tothe write-up from Chalmers University of Technology:

The structural battery uses carbon fibre as a negative electrode, and a lithium iron phosphate-coated aluminium foil as the positive electrode. The carbon fibre acts as a host for the lithium and thus stores the energy. Since the carbon fibre also conducts electrons, the need for copper and silver conductors is also avoided – reducing the weight even further. Both the carbon fibre and the aluminium foil contribute to the mechanical properties of the structural battery. The two electrode materials are kept separated by a fibreglass fabric in a structural electrolyte matrix. The task of the electrolyte is to transport the lithium ions between the two electrodes of the battery, but also to transfer mechanical loads between carbon fibres and other parts.

The researchers realize there’s plenty of room for improvement, if they want to compete with lithium ion batteries for energy density. With that in mind, they’re working on a new project with financing by the Swedish National Space Agency. They’re hoping to reach an energy density of 75 Wh/kg and a stiffness of 75 GPa. This make the battery as strong as aluminum, but with less weight.